Cloud Connection Gateway for Coffee Machines

IoT system for remote management of professional coffee machines

Client

Request

Imagine being the owner of a bustling bar or café where thousands of coffees are prepared every day. Have you ever thought about how useful it would be to have digital access to data regarding the usage of your professional coffee machine? This functionality offers numerous advantages, allowing you to optimally manage orders and consumption, resulting in significant savings.

With this in mind, the Tuscan company La Marzocco, which has been producing and distributing high-end espresso machines for over ninety years, embarked on an ambitious project: transforming its products into modern IoT (Internet of Things) systems, intelligent and connected. The goal is to offer an increasingly digital and simplified experience to its customers, whether they are baristas, coffee enthusiasts, or lovers of excellence.

Solution

Methodology

- Agile

Services Involved

- Embedded software development

- IoT systems

- Continuous Integration with HIL (Hardware-In-the-Loop)

Tecnologia

Do you need support for your project?

Risult

We worked closely with La Marzocco’s R&D department to develop the project: dedicated software for acquiring data generated by coffee machines, which are subsequently stored on a remote server. In particular, we completed the development of connection software, enabling machines to communicate with the cloud, sending and receiving data via a dedicated gateway.

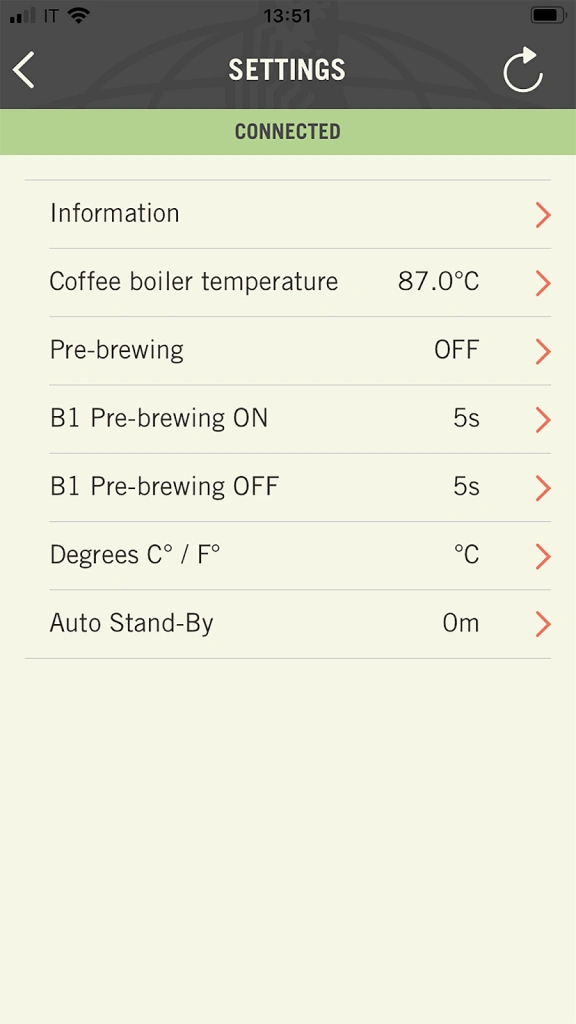

Through this remote connection, we can gather various information about the machines, such as the quantity of coffee dispensed and the type of coffee prepared (espresso, lungo, ristretto, etc.), along with data on energy consumption and other information useful for future purposes, such as predictive maintenance. This connection has also allowed the introduction of new and very interesting features. For example, thanks to remote control, it is possible to start heating the coffee machine via an app, so that it is ready for use when needed. Furthermore, the remote connection allows linking the machine to a testing system used by La Marzocco in the production phase.

La Marzocco attaches great importance to this project and has dedicated a section of its Coffee Academy to this specific area of IoT.

The entire project was implemented using the Go programming language and Linux Embedded, following a technology stack specifically designed for IoT, including the use of the MQTT protocol. Data generated by the machines are saved on an AWS (Amazon Web Services) cloud system. Through Continuous Integration with HIL (Hardware-In-the-Loop), we combined software and hardware development, conducting continuous tests in a simulated environment: this allowed us to reduce time and costs and improve product reliability and quality.

Advantages

- Integration

In this extremely challenging project, we managed to combine the use of advanced technologies with La Marzocco’s artisanal product. - Efficiency

Coffee machines become intelligent, digital, and connected tools capable of communicating real-time data, providing detailed information, and supporting professionals in achieving the best results.

Conclusion

Through the implementation of IoT solutions, the company aims to fully leverage the potential of connectivity to make the coffee experience even more engaging and personalized. With its commitment and long tradition of excellence, La Marzocco is at the forefront of the professional coffee machine industry, embracing digitalization and sustainability to meet the ever-growing needs of its customers.

We are satisfied and honored to collaborate with this Tuscan partner, to whom we are linked not only by the territory but also by the attitude towards experimentation and innovation: we are already working on new projects together!